What is quality management with IMS software?

Kirjoittaja:

The purpose of a quality system is to simplify the organization’s operations and help the organization improve its operations

IMS software is a platform available to the entire organization, where a quality system tailored to the organization’s needs can be built. IMS software operates as a cloud service, eliminating the need for separate installations, and the use and maintenance of the system are independent of location – the software only requires an internet connection.

- The purpose of a quality system is to assist your organization in everyday tasks by making information discovery, maintenance, and sharing easy.

- A quality system standardizes and improves organizational functions by making information transparent.

- Using IMS software, you can build a quality system, management system, or operational system tailored to your organization’s needs.

Quality management begins with documenting operations – IMS software allows you to document all work-related information in one system

- IMS software is built to meet the requirements of ISO standards.

- IMS software consolidates all work-related information and facilitates information management and maintenance. In IMS software, it is possible to assign inspection, approval, review, and versioning practices to different roles within the organization.

- In IMS software, it is possible to link information together, for example, performance metrics, risks, documentation, or deviation report templates can be linked to process descriptions.

- In IMS software, the organization documents its operations in the form of processes and work-related documents. This makes it easy for the entire organization to create high-quality practices, such as ISO-compliant quality management, tailored to your needs.

- By documenting your operations, you also lay the groundwork for business development: When the organization has described its starting point, you can monitor and measure the progress of operations reliably, enabling systematic continuous improvement of operations.

IMS software facilitates the implementation of quality management methods and engages the entire organization in quality management

With IMS software, the organization can implement key quality management methods in its daily operations.

- Proactive quality assurance actions – things are done right the first time with operation documentation, such as quality manuals, process descriptions, and instructions.

- Quality control actions – testing, measurement, and reporting. Making quality monitoring easy, for example, by facilitating data collection, reporting, and measurement of operations, as well as implementing and monitoring reported observations and corrective actions. You can also facilitate the planning, implementation, and monitoring of internal audits with IMS software.

- Quality improvement actions – learning from mistakes. When monitoring, measuring, and reporting operations are systematic, errors become apparent, and it becomes easier to correct operations when the cause of the error is known. If processes are not described or instructions are not documented in the organization, it can be difficult to identify which part of the process needs improvement.

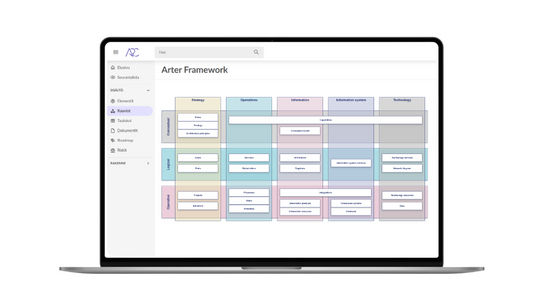

IMS software consists of sections that correspond to the requirements of ISO standards

IMS software consists of sections that are required by organizational operations, such as ISO standard. IMS software consists of

- processes,

- documents,

- manuals,

- indicators,

- reports,

- and risk management.

With IMS software, you can build a quality system tailored to your organization’s needs

With IMS software, you can build a quality system tailored to your company’s needs, allowing you to:

- Describe and develop processes.

- Manage and maintain work-guiding documentation.

- Create and maintain manuals.

- Measure operations through feedback collection, near-miss situations, and deviation logging.

- Implement systematic risk management.

Lue lisää

-

Published on:

Published on: -

Published on:

Published on:Documenting processes with The 3-page technique

-